3D Printing & AM

Metal powders Choice

For different spare parts, you may need different metal powders to fit for the parameters or effect

you wanna to get. Such as strength, yield strength, hardness etc. For pro suggestions, contact us any time.

| GH4169 | In718 | 0-20μm | 15-45μm | 15-53μm | 15-38μm |

| GH3625 | In625 | 0-20μm | 15-45μm | 15-53μm | 15-38μm |

| C276 | 0-20μm | 15-45μm | 15-53μm | 15-38μm |

| In713C | 0-20μm | 15-45μm | 15-53μm | 15-38μm |

| In738LC | 0-20μm | 15-45μm | 15-53μm | 15-38μm |

| In939 | 0-20μm | 15-45μm | 15-53μm | 15-38μm |

| C276 | 0-20μm | 15-45μm | 15-53μm | 15-38μm |

| NiCr25 | 0-20μm | 15-45μm | 15-53μm | 15-38μm |

| GH3230 | 0-20μm | 15-45μm | 15-53μm | 15-38μm |

| GH3536 | 0-20μm | 15-45μm | 15-53μm | 15-38μm |

| CrCrMo | 0-20μm | 15-45μm | 15-53μm | 15-38μm |

| CrCrMoW | 0-20μm | 15-45μm | 15-53μm | 15-38μm |

| CoCrW | 0-20μm | 15-45μm | 15-53μm | 15-38μm |

| Bronze | CuSn10 |

| CuCrZr | Cr 0.3-1.2 Zr 0.03-0.3 Cu Bal |

| CuCrNb | Cr 3.1-3.5 Nb 2.5-3 Fe<0.01 Si<0.025 Cu Bal. |

| CuAlNiFe | Fe 3-5 Ni 4-6 Al 8.5-11 Cu Bal. |

| CuNiSiCr | Cr 0.2-0.5 Ni 2-3 Fe≤0.15 Si0.5-0.8 Cu Bal. |

| AlSi10Mg | Si 9-11 Mg 0.25-0.45 Al Bal. |

| AlSi7Mg | Si 6.7-7.5 Mg 0.45-0.75 Al Bal. |

| ADC12 | Si 9.6-12 Cu 1.5-3.5 Al Bal. |

| 2024 | Cu 3.8-4.9 Mg 1.2-1.8 Mn 0.3-0.9 Al Bal. |

| 2219 | Cu 5.6-6.8 Mn 0.2-0.4 Al Bal. |

| 4043 | Si 4.5-6 Al Bal. |

| 4047 | Si 11-13 Al Bal. |

| 5A06 | Mg 5.8-6.8 Mn 0.5-0.8 Al Bal. |

| 5083 | Mg 4.5-4.9 Mn 0.4-1 Cr 0.05-0.25 Al Bal. |

| 6061 | Si 0.4-0.8 Mg 0.8-1.2 Cu 0.15-0.4 Cr 0.04-0.35 Al Bal. |

| 7A04 | Zn 5.0-7.0 Mg 1.8-2.8 Cu 1.4-2.0 Mn 0.2-0.6 Al Bal. |

| 7075 | Zn 5.1-6.1 Mg 2.1-2.9 Cu 1.2-2 Cr 0.18-0.28 Al Bal. |

| 7050 | Zn 5.7-6.7 Mg 1.9-2.6 Cu 2.0-2.6 Al Bal. |

More 3D Printing Metal Powders

Dental Metal Powders

–CoCrMoW | CoCrW | CoCrMo | TC4 | NiCr25

Jewelry

–925 Silver | Brass Powders | Bronze Powders | Cu Powders | Stainless Steel Powders

Aerospace & Molds & Automobile, Medical Devices

–TC4 | |CP-Ti |TA1 | TA 15 | AlSi10Mg | Steel Alloy Powders | Nickel Alloy Powders

Laser Cladding

–430L | Fe Alloy Powders | C22| C276 | FeCrV |More Nickel Alloy Powders

……

Metal Powders Application

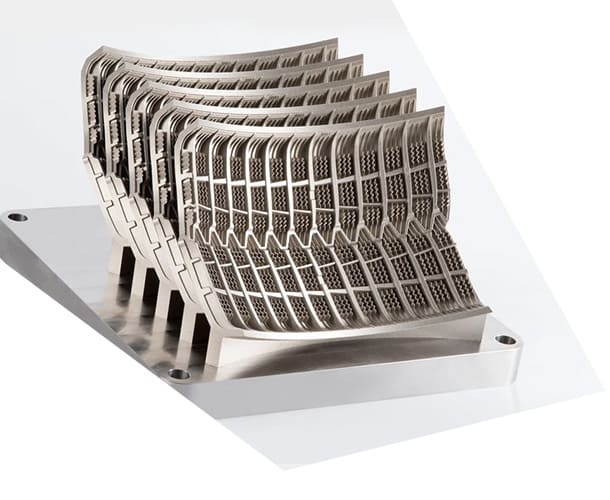

3D Printing & Additive Manufacturing

Automation

Lightweight, cost-efficient & customer-specific

Toolings

Lightweight, cost-efficient & customer-specific

Aircraft & Space

With reduced weight and improved performance to create worthy parts

Medical

Broad range of RPD frame, crown/bridge, sub-frame, etc.

Eletronics

A number of consumer sporting equipment products and parts was produced by metal powders

Consumer

Jewery, glass frames, kinds of consumer goods are widely used metal powders

Energy

Fabrication of complex devices in the energy sector.

Turbines

Aerospace industries are leading the innovation and implementation of additive manufacturing

Frequently Asked Questions

Spherical or spheroid both great materials for 3D printing and additive manufacturing. And we also developt one kind of spheroid titanium metal powders this year, the parameter of it is even much better than spherial ones.

The most common production technology of 3d printing metal powder is atomization, and it also divided into water atomization and gas atomization. Oxgen content of powder would be totally different. So if you have some special parameter requirements, be sure to contact our experts.

Electron Beam Machining (EBM),Laser Direct Melting Manufacturing Technology (DMD ),Direct Metal Laser Sintering (DMLS),Selective Laser Sintering (SLS), Selective Electron Beam Melting (SEBM )etc.

15-45μm

15-53μm

15-150μm

53-153μm

53-105μm

Above are normal particle size .

Yes. But please offer us below information:

- Quantity

- Particle size requirements

- Composition requirements

- End application

Get an instant quote

What kind of products you are planning to put into production? Contact us to get the most pro suggestions and get paid samples today.